-

Product Description

-

Materials & Properties

-

Processing. Knowhow

-

Product Description:

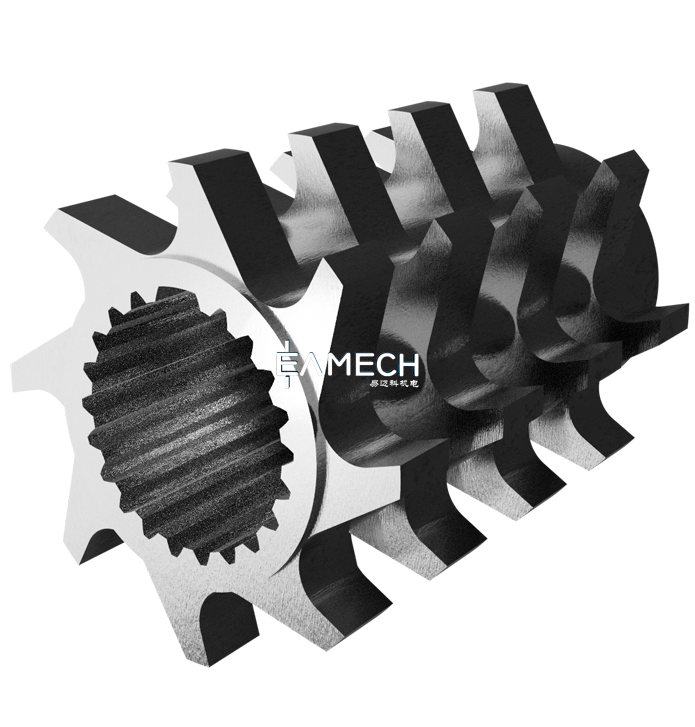

· TME is a toothed disc screw element, usually used in the melting and kneading section of the polymer. The TME have diffirence types, like forward teeth or reverse teeth, which can be paired with one forward and one reverse teeth. It is also available to use in series with two or three forward discs. The staggered tooth shape can divert and plasticize the material, but the conveying capacity is weak. The toothed mixing elements are conducive to dispersion and distributed mixing, and the energy consumption is normal. There can be multiple combinations of component selection, which can be continuously optimized during the implementation-correction-re-implementation-re-correction process.

· ..

-

Materials & Properties:

Material Description Nitrided steel(38CrMoAlA): Nitriding treatment, high hardness and corrosion resistance, suitable for common conditions

High-speed tool steel(W6Mo5Cr4V2): Vacuum quenching, overall hardening screw elements, high wear resistance, strong toughness, used in glass fiber reinforced,high filling and so on; Stainless(316): Used in anti-corrosion, anti-rust and food conditions; Hastelloy alloy: Nickel-based alloy, mainly used in the processing of fluorine plastics; Others: WR5,WR13,WR14, ETC., Processing range:φ20 mm ~φ175 mm, only for Twin Screw Extruder.

· All internal splines of screw elements are manufactured according to GB or DIN standards.

Structure:

SCREW ELEMENT

Data:

1、Diameter of screw element (include: outer diameter & root diameter of tscrew element); 2、The pitch of screw element and the picture of that; 3、Number of internal spline teeth (top diameter and root diameter); 4、The brand of twin screw extruder;5、 the type of extruder;

-

Processing. Knowhow:

· 1. All component materials are sourced from reputable material suppliers. To guarantee the quality of raw materials, we conduct both elemental and metallographic analyses;

· 2. Screw Elements are finished by CNC grinding;

· 3. The professional technical team can not only provide surveying and mapping business, but also provide technical services in component combination.